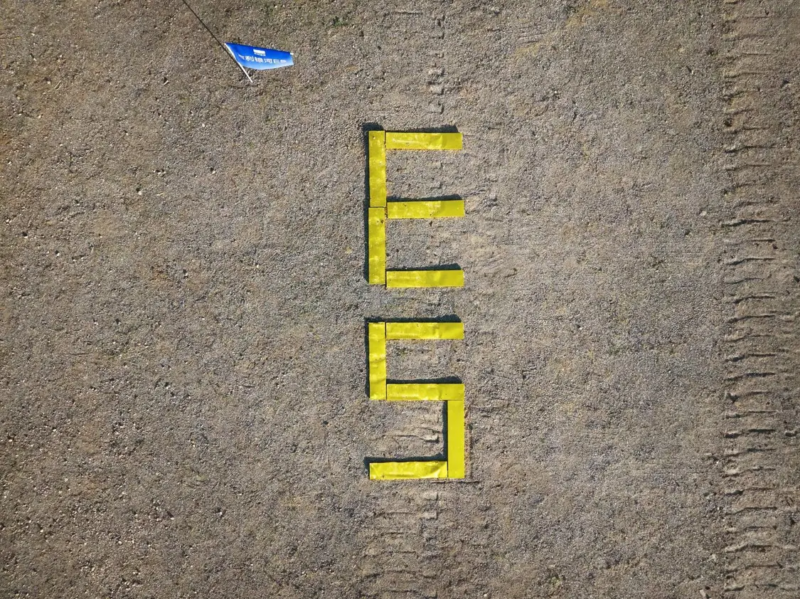

In a demonstration of battery safety technology, Geely‘s Galaxy E5 electric vehicle has completed an extreme compression test where its “Aegis Gold Brick Battery” withstood the crushing weight of a 36-ton ZTZ-59D medium tank. The pressure applied during this test was approximately 1.8 times higher than what is required by China’s new national battery safety standards, with no signs of fire, explosion, or thermal runaway observed in either the battery pack or individual cells.

The test simulated a scenario where a vehicle’s battery undergoes extreme external impact and compression. The 36-ton tank repeatedly drove over the battery pack with its tracks, then crushing individual battery cells and a group of ten cells. Despite this extreme pressure, the battery pack maintained its structural integrity with no bulging, leakage, fire, or explosion. Professional inspection confirmed that the battery endured compression forces exceeding the new national standard requirements.

New national battery safety standards

On March 28, China’s Ministry of Industry and Information Technology announced new safety requirements for electric vehicle power batteries (GB38031-2025), which will be implemented starting July 1, 2026. These updated standards introduce three core safety improvements:

- New safety testing after fast-charging cycles

- Enhanced thermal runaway protection requirements

- First-ever bottom impact testing

Geely’s Aegis Gold Brick Battery system has already passed these new standards, becoming one of the first battery brands in the industry to receive full certification.

The Aegis Gold Brick Battery features a short length, increased thickness, low internal resistance, and minimal heat generation. It employs high-quality materials, including a more flexible wet-process dual-coated separator with an aluminium oxide heat-resistant coating, which prevents cell rupture and thermal runaway when punctured.

The battery pack boasts industry-leading IP68 and IPX9K protection ratings, CTB (Cell To Body) integration technology, grid structures with four energy-absorbing cross-sections, and a 2.6mm thick “sandwich” structure bottom plate. The battery design incorporates liquid-electric separation, electrical isolation, heat dissipation, and multiple protective measures to enhance safety.

Exceeding safety standards

While the new national standards require 24 safety tests, Geely subjects its Aegis Gold Brick Battery to 36 extreme scenarios, with 23 tests exceeding national requirements. Geely has also proactively implemented the new “bottom impact” test in its corporate standards and plans to open its battery safety patent portfolio to the entire industry.

The Galaxy E5 has previously achieved excellent results in extreme high-temperature tests and comprehensive safety trials conducted by the China Automotive Technology and Research Center (CATARC). It has earned NESTA six-dimensional electrical safety certification and five-star safety ratings from Euro NCAP and ANCAP.

Geely Galaxy vehicles have accumulated nearly one million sales with zero spontaneous combustion incidents, demonstrating the effectiveness of their safety technologies. Later this year, it plans to open its Global Comprehensive Safety Test Center—the world’s largest single safety test laboratory—to the industry.